With over 30 years of experience developing technology for the pharmaceuticals market, SEA Vision is a long-standing partner to the market that provides solutions for industrial vision, traceability systems and automation processes. Marketing Manager at SEA Vision Maria Grazia Preda talked to us about the innovations the Pavia-based company will be showcasing at the simultaneous Pharmintech and Ipack-Ima 2025 events.

Both events provides a key opportunity to engage first-hand with international customers, partners, and players in the pharmaceutical industry. It is an excellent occasion to present our innovative solutions and discuss the latest trends, so that we can continue to tackle the challenges of the pharmaceutical market.

We are focusing on three main areas. First of all, track and trace: in the traceability sector, which is one of the most important areas of our core business, the spotlight will be on the European directive on traceability coming into force in Italy too, which is a key issue at the moment. For Italian customers that are not serialising yet, we will be showcasing all our modular solutions designed to ensure they are compliant by the deadline established by the directive. We will have a machine incorporating the traceability software on show at the stand and our entire team will be on hand to take customers through the procedure step by step, explaining all the features and operational details that they will have to introduce. In addition to this, we will be showing them the areas in which we are developing complementary traceability solutions, highlighting key projects where significant product advancements are being made.

The second area we will be focussing on is RFID, which we will be exploring through the presentation of a pioneering project we are working on, concerning the implementation of an RFID tag tracking system for syringes, to guarantee greater quality control for the products handled.

The third area is centralised palletisation. A complete, integrated software solution that allows palletised cases to be grouped together using a single palletising island for multiple lines. This automation solution completes palletiser operations and optimises the equipment footprint and investments.

Of course, there is no shortage of AI applications in vision systems and visitors at the fair will have the chance to preview the concept behind our new Harleblister Neurale. An innovative version of the first inspection system for solids in blister packs that SEA Vision presented on the market exactly 30 years ago, the system has now been enhanced through the introduction of AI algorithms. These algorithms mean greater efficiency, improved inspection performance, and above all more user-friendly operation, as many of the settings which were previously handled by operators are now set directly by the system.

The integration of AI into our vision systems dedicated to the pharmaceutical world is an ongoing process at SEA Vision. To support the process, we have merged the development teams at ARGO Vision - a start-up acquired in 2021 specialising in AI - and the SEA Vision team, with the aim of improving the accuracy and performance of vision systems for quality control for drugs through upgraded techniques and technology.

In addition to ensuring even greater safety during inspection processes, the integration of AI makes the Harleblister increasingly intuitive and easy to use, optimising both production and control parameter setting. This enables operators to work more efficiently and considerably reduces setting times.

Finally, completing the overview of the system's features, process digitalisation and automation is powered by yudoo, the software suite for the digitalisation of production processes which also includes automation and data analysis. Equipped with a user-friendly interface, yudoo establishes smart connections with automation devices, machinery, IT, and control systems, revolutionising production management in the pharmaceutical industry. The software centralises all the functions and features required for the management and supervision of production departments. The yudoo suite digitalises every aspect of operations, connecting up all the company's information and operational technology systems. from ERP and MES to vision systems, from machinery to individual devices like printers.

In its complete version, yudoo includes features for managing production lines, for integrating existing track and trace architecture for serialisation management, and for real-time analysis of OEE and advanced KPIs based on business intelligence tools, to provide strategic business insights.

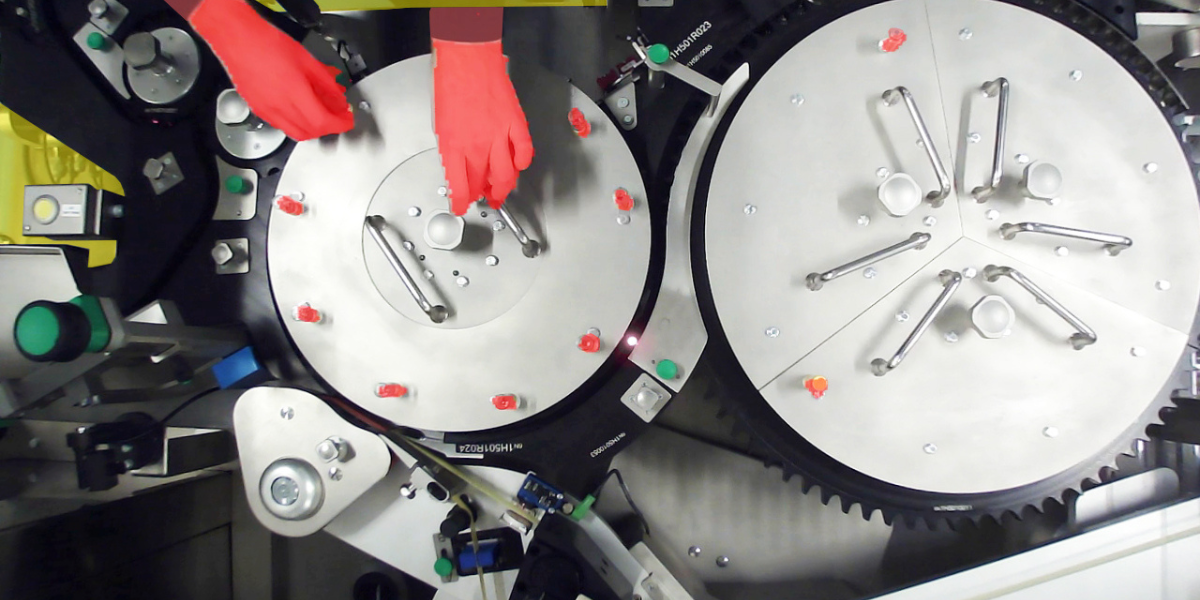

At the next events, we will be presenting significant innovations that combine sustainability and digitalisation, focussing specially on our AI powered solution for automated line clearance, "a-eye clearance". Developed by SEA Vision and ARGO Vision, a-eye clearance is the revolutionary new technology that uses artificial intelligence to increase efficiency and safety during line clearance process. The aim of this innovation is to ensure machines are perfectly clean and that there are no residues from previous batches, to minimise the risk of errors and improve overall production quality.

This new solution, a-eye clearance, allows users to automate and digitalise clearance procedures on packaging lines, for enhanced safety and smoother processes. The software can conduct accurate automatic inspections of the work areas on the lines using industrial cameras, smart sensors, or scanners. The software is powered by AI algorithms to automate procedures, highlight anomalies, provide real-time feedback, increase OEE, and speed up product changeovers.

This solution offers a concrete example of how SEA Vision is working to help companies improve production efficiency, while also reducing waste and promoting more sustainable operations.

The industry is moving towards increasingly integrated automation, artificial intelligence, and sustainability. On the one hand, customers require increasingly customised solutions that cater to their needs as they arise and also reduce costs and production times. On the other hand, there is a growing focus on environmental impact and optimising production processes to reduce waste and improve efficiency. We are confident that production in the pharmaceutical industry will be increasingly based on innovative technologies in which AI and digitalisation play a central role, so as to achieve ever-more ambitious quality and sustainability standards. Thanks to the solutions we bring to the market, this is not only a possibility, it is already a reality.